Different shapes of metal mesh

One of the main differences regarding expanded metal is precisely that relating to its geometric shape.

The most common shapes of metal mesh are:

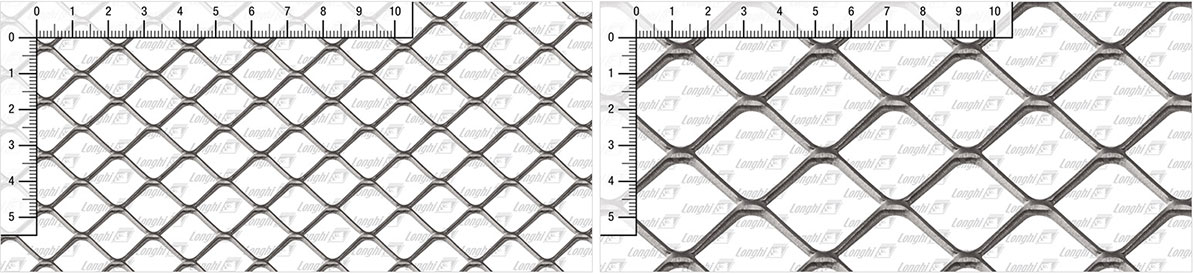

- Square metal mesh

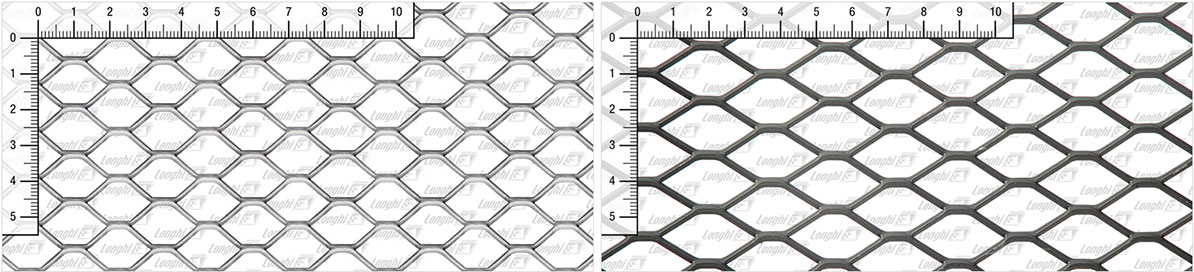

- Hexagonal metal mesh

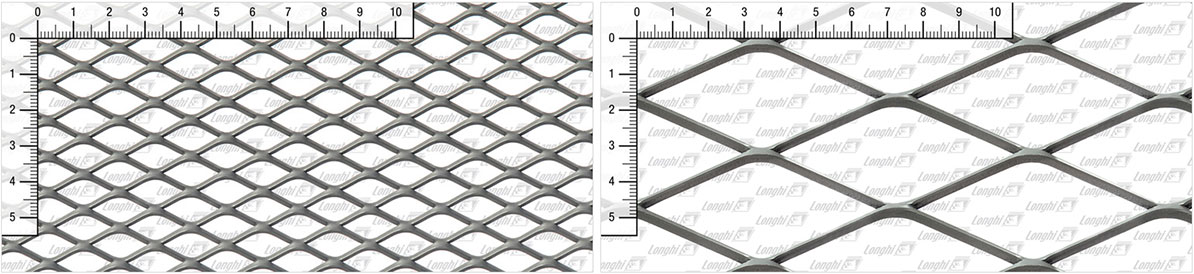

- Rhomboid metal mesh or also known as diamond metal mesh

They can be produced in different materials.

Among the three, one very used shape is the square one (flattened and not).

It is possible to make square expanded metal sheets in sendzimir carbon steel, aluminum and copper and can also be personalized by request.

The 'Sicura Net' square mesh is used for various kind of protections, it has been tested for the safety of moving gates, with reference to the UNI EN 12453 standard. The width of its opening prevents 'shearing' accidents. It represents one of the 'historical' products of the L HOLDING company.

The hexagonal shape is also used in a lot of projects.

As in the case of the square mesh, also the hexagonal one can be made in sendzimir carbon steel, aluminum and copper and customized according to requests.

An example of the use of this hexagonal metal mesh is the setting up of the Campo Marzio Store.

As you can see, from the thin openings of the expanded mesh you can see beams of light that make the atmosphere suffused and elegant.

The third shape, the diamond metal mesh, is also made in different materials according to the different requests.

We are talking about a very resistant type of sheet metal that can be made, also in this case, in sendzimir carbon steel, aluminum and copper.

In addition to the classic diamond shape, Fils offers a “diamond mesh flatt”, which allows you to get a smoother and flatter surface.

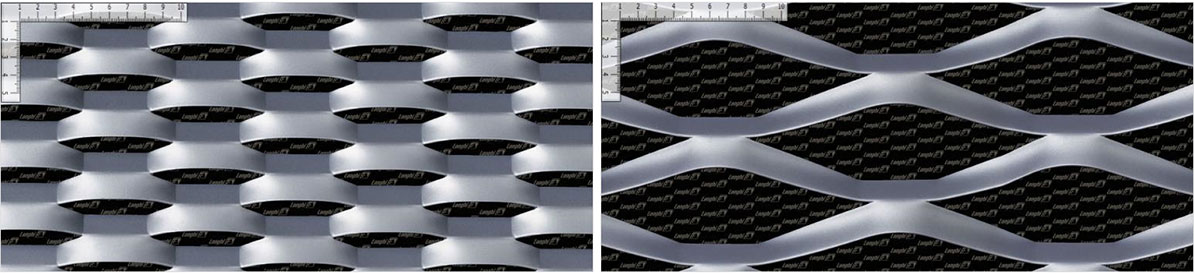

For applications in the field of architecture, the PROTECH Line is available, a wide range of metal meshes that derive from the basic hexagonal and rhomboidal shapes of expanded metal and present pronounced strand width. This feature makes them particularly suitable for coatings. Many variations are also available for an original choice. For example, the ACADEMY, a diamond expanded mesh was used for the WJC, the World Join Center.

The main advantage of expanded metal is the possibility of processing this raw material with zero waste because we can cut it as the customer wants realizing bordered, curved and folded sheet of expanded metal according to the use that he needs.

Another important advantage lies in the molding process: the “ironing” takes place cold, thus not requiring the use of pollutants and not providing for harmful emissions.

What we are talking about is really a very interesting material both from a functional and aesthetic point of view: the history of metal mesh starts from ancient Egypt to arrive in the 90s to knock on the door of important architects who have recognized immense potential in this material.

From a functional point of view, as we have already said, it is a sustainable raw material, 100% recyclable, uses photovoltaic systems for production and guarantees excellent protection.

From an aesthetic point of view, on the other hand, we have already referred to creativity and the particularity / uniqueness that expanded metal is able to ensure for any type of project.