All about metal mesh

Let's take a look at the evolution of metal mesh’s use

In the most recent decades, there have been many discoveries and innovations that have concerned the field of industry and architecture. The discovery of new “building products” is linked not only to the desire to give vent to the inherent creativity of designers and architects but also to the possibility of knowing and using materials with excellent performance and intended uses.

This is exactly what happened with the discovery of the use of metal mesh in many fields of application.

But first let's take a look at the evolution of metal mesh’s use and how it came to be used in industry and architecture.

One of the first uses of the wire metal mesh, documented by historians, dates back to the period of ancient Egypt when it was used for the creation of jewels, a practice that, later, was taken up by the Vikings with the same purpose.

Things start to change from the V Century onwards, when the use of wire mesh begins to be considered important in various fields of application: in the textile sector, thanks to the growth that was experiencing, it was soon realized that it was possible to weave metal wire.

The Chain mail, also called Mail, was a form of body armour worn by European knights and other military men throughout most of the medieval period.

The metal wire mesh was only one of the first materials whose use was found in history: subsequently, perforated sheet metal and expanded metal are two other categories of materials similar to metal meshes, or metal nets, which have their presence in the market progressively asserted themselves and have been adopted for ever increasing uses in various industrial sectors.

In fact, the versatility of its characteristics leads the wire mesh to be a product with high industrial use, especially in the sectors of filtration, soundproofing and carpentry in general.

Not to mention the ever-growing examples of applications of metal mesh in architectural coatings described later in the article.

For example, see the vault of the entrance to the Baku airport in Azerbaijan made of expanded metal.

The generic term metal mesh therefore refers to a world of applications (from art to carpentry) and products that are also very different from each other in terms of aesthetics and functionality.

We therefore classify this wide field into three more specific sectors:

- Expanded metal mesh

- Perforated metal mesh

- Wire metal mesh

1) Expanded metal mesh

Expanded metal mesh is so defined because it is the result of the incision and cold drawing of the metal (the 'expanding process')

In this way a resistant semi-finished product is obtained with a continuous structure with no joints.

Since the coil of material is stretched and not perforated, this process is optimal as it minimizes the waste of the material used.

The materials that can be used to such processing are many, we can mention carbon steel, stainless steel, aluminium, copper, brass and titanium.

The applications of this product are many and they differ according to their size and the thickness of the sheet.

Micro meshes, expanded metal mesh with very small incisions, will be suitable for the filtering business. Stainless steel is the most used material thanks to its high resistance. The shapes of the expanded metal filters are several and it can also be combined with components required by the intended use of the filter itself: ring nuts, handles, solid edges and other accessories for completion.

Bigger expanded metal meshes instead has been used over time by many architects and artists, attracted by its shapes, used it for such different works. In addition to aesthetic purposes, expanded metals represent a highly resistant alternative to weathering and degradation.

2) Perforated metal mesh

Perforated metal, also known as perforated sheet, is sheet metal that has been punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns.

The types of perforated sheet can be different depending on the geometry of the hole: round, square or 'patterned' hole. The uses of perforated sheet metal are so many: it is possible to create protections, dividing walls and other applications of carpentry and architecture.

3) Wire metal mesh

Wire mesh is a metal mesh that can be used in different ways thanks to the ease with which it can be customized according to different needs.

The production process takes place through the weaving of "wires", which are usually made of stainless steel (metal links in copper or titanium are less used).

The essential elements are:

1) the type of wire and its diameter

2) the weft: made up of wires parallel to the width of the metal fabric

3) the warp: made up of wires parallel to the length.

The difference between the various types of matting nets is given precisely by the set of these three elements, i.e. by the type of yarn used and by the pitch between warp and weft thus obtaining different metal nets (with wider mesh, shorter mesh, more resistant etc.) applicable for different uses and purposes.

We have seen that metal mesh can be used in different ways for several decades - also in a rather unusual and particular way that we tell you here.

A common and frequent use is that of applying wire mesh to the facades of buildings or even inside them, creating functional and aesthetically beautiful structures.

Let’s see the main application of metal mesh.

1) Metal mesh as an external cladding: facades in metal mesh

One of the main uses of expanded metal mesh is to cover buildings facades.

The projects we have carried out around the world show how the use of metal mesh panels for the facades has been a winning move because they are able to give the building elegance - with a stunning visual effect - and at the same time, excellent protection from the sun.

The versatility and ease with which this material is cut to assume different shapes (bordered, curved and folded), allows you to create personalized and unique facades.

Here, some of our works:

To see other facades realized by us just read this article.

The reason why this material is used in this way is to be found in its performance characteristics, like:

- resistance to atmospheric agents

- guarantees excellent stability to the structure

- resists the action of the wind and impacts

- protects from the sun by acting as a screen (paying attention to the type of mesh and its size)

- protects the building from vandalism as it is not possible to damage it with writings, for this reason it is used in stadiums, halls, schools, etc

- according to the transparency variables it is able to become transparent or reflective

2) Metal mesh as false ceilings

Another highly sought-after way to use wire mesh in architecture is the one involving the creation of false ceilings. The three-dimensionality of the metal mesh allows to hide light points and systems and to give a magnificent acoustic and visual comfort.

Just few our works:

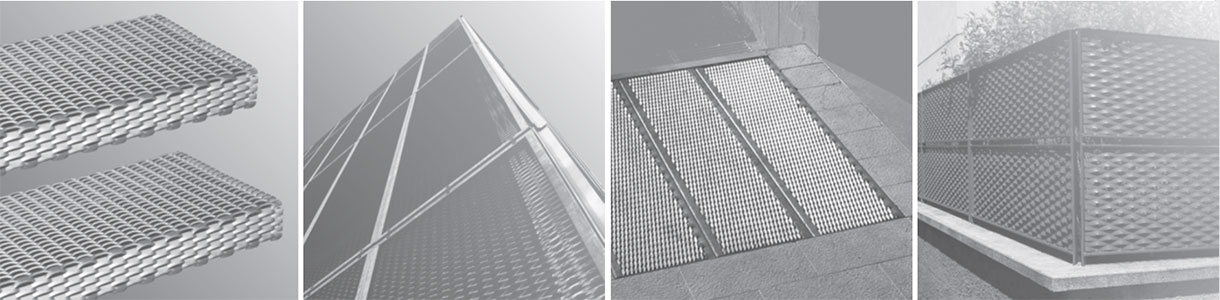

3) Metal mesh as out-fitting

Thanks to its stage presence, metal meshes are often also used to attract and communicate a product or service with particular out-fitting like stands and store windows, furnishing.

4) Metal mesh as fencing and parapets

The protection of your spaces (home or work) is a factor not to be overlooked. The metal mesh guarantees the right privacy and protection and it is possible to customize it in shape and color like this fencing:

or this parapet in expanded metal:

5) Metal mesh as sun shades

As we said before, one of the reasons why the metal mesh is used to cover the facades of buildings is linked to solar control, to the filtering of sunlight that allows well-being and energy efficiency.

These sunshades in expanded metal mesh allow a limited passage of heat reducing the need to operate heating systems in the summer season.

We have learned so far which are the main uses of metal mesh which, thanks to its performance, is widely used in the architecture and construction sectors.

In summary, the main advantages of expanded metal mesh are:

- high resistance to mechanical stress thanks to the characteristics of the material

- extensive range of aesthetic patterns

- protection from atmospheric agents

- absence (limitata) of maintenance

- excellent durability over time

- possibility to give stability to the entire structure (even if it’s a huge one)

- possibility to recycle it

- possibility to put it on new or existing buildings

- good shielding from sun and light

- protection from vandalism

- in the construction sector, it’s perfect to keep safe the staff and equipment with dividers and non-slip gratings

- ease in shaping and processing

- innovation, as it allows you to use it for more complex and particular projects

- cheap, because processing without waste allows you to lower costs by avoiding waste.

It is not surprising that this product has been very successful in these sectors thanks to its versatility and to the excellent performance it allows.

Whether it is to cover facades or to set up a showroom or even to create covers for industrial machines, an important thing to establish with a professional technician is the size of the metal mesh and therefore the right texture of metal mesh that is needed.

Basically, we have the micro expanded metal mesh or the tightly woven wire mesh and the large ones.

The choice between one and the other mesh size depends exclusively on the situation, in order to meet specific needs.

And that’s the reason why, very often, we advise our customers to speak with experts in order to perfectly understand their needs in order to be able to choose a standard or customized expanded metal mesh.

Establishing a precise price for metal mesh is not easy since there are many factors that contribute to varying the price (size and type of metal mesh as needed).

We are ready to satisfy all the requests of our customers (whenever possible) because the material allows us to be flexible and to realize exactly what the customer asks.

If you are interested in our service just contact our expert and ask them everything you want and you need so you can get an idea of the overall expense.

So far we have seen (some of) the great projects we have made with metal mesh all over the world, but we also use metal mesh to produce other standard products, in common use, which ensure quality and durability over time.

Our finish products in metal mesh are:

- a new concept of protection that allows you to have the right view and at the same time to have all the privacy you’re looking for. It is clear that everything depends on the width of the metal mesh;

- grating and support frame for walkways;

- manhole and gully covers for draining the water;

- stair-treads and landings in different types of metal mesh and also made to measure. They are: anti-slip, anti-heel, anti-ice, anti-panic. In this page you can find all the information about the models of stair treads available in stock and also the landing available and all the advantages of this type of finished product.

- quality doormats

The walkways also represent a strong point for our company because they are certified according to the legislation in force (NTC 2018 - Ministerial Decree of 17/01/2018) , making them one of the best products in circulation.

At this point, we are pleased to list all the works we have done around the world. Inside and outside. Small and large.

Our Interiors: the magic of metal mesh to create functional and design environments:

- Knoll International Milan (IT)

- Autosalone Sondrio (IT)

- Stand Cristina Rubinetterie Bologna (IT)

- Illy Galleria Trieste (IT)

- Palasport Olimpico Hockey 1 Turin (IT)

- Rassegna Culturale ex Chiesa di Sant’Agostino Bergamo (IT)

- Interiér Staroměstské Radnice Praha (CZ)

Our Exteriors: strong and imposing structures but at the same time elegant and (almost) floating:

- Centro WJC, Milan (IT)

- Società GUNA Milan (IT)

- Cinema Multisala Porta Nova, Crema (IT)

- Centro Comercial Berceo, Logroño (ES)

- Centro Direzionale e Residenziale, Bergamo (IT)

- Hotel “La Dolce Vita”, Bergamo (IT)

- Migros WÜRZENBACH, Luzern (CH)

- Alzano PalaSport, Bergamo (IT)

- Campos Empresarial de Navarra, Pamplona (ES)

- Unterwerk Blattenmoos, Littau (CH)

- Step de Bois-de-Bay, Satigny (CH)

- Centro Municipal de Empresas Innovadoras IGARA, San Sebastián (ES)

- Institutsgebäude und Versuchshalle der TU, Darmstadt (DE)

- Wohnüberbauung Rotseepark, Luzern (CH)

- Spirig, Egerkingen (CH)

- Zuwebe, Baar (CH)

- Ports Francs et Entrepôts de Genève SA, Les Acacias - Genève (CH)

- L'odyssée Complexe Aquatique, Chartres (FR)

- Amag Grabenhof, Kriens (CH)

- Hemag, Balgach (CH)

Other works:

- Sovrappasso ferroviario Grugliasco, Turin (IT)

- Aéroport Enfidha Zine El Abidine Ben Ali, Tunisie (TN)

- Tour Vigie ADP, Roissy (FR)

- Hotel Aarau-West, Oberentfelden (CH)

- Centre Hospitalier Louis Pasteur, Dole (FR)

- Ponte degli Alpini, Belluno (IT)

- Edificio de Oficinas “Cerro de los Gamos”, Madrid (ES)

- Centro Commerciale Ipercoop Montedoro, Muggia - Trieste (IT)

- Concessionaria auto, Omegna - Verbania (IT)

- Colegio Público Hnos. Amorós Fernández, Las Mesas - Cuenca (ES)

- Grands Moulins Université Paris Diderot, Paris (FR)

- Lávka pro pěší přes komunikaci, Patočkova - Praha (CZ)

- Pont de Mitrovica, Kosovo (SRB)

- Sovrappasso ferroviario Pordenone (IT)

- Campo de Fútbol de Lasesarre, Barakaldo - Bilbao (ES)

- Piscina Centro Universitario Sportivo - Parco d'Orleans, Palermo (IT)

- Casaluci Castrignano dei Greci, Lecce (IT)

- Fiera di Foggia (IT)