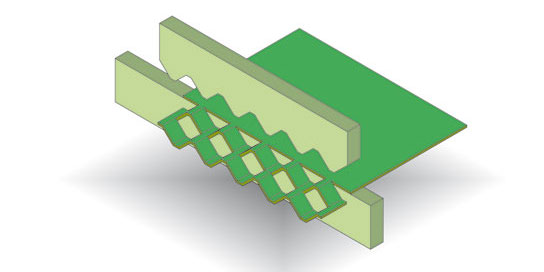

How expanded mesh is made

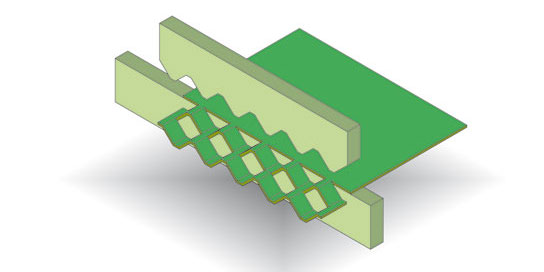

The shape of the blades used to cut the sheet metal determines the shape and size of the expanded mesh. The semi-finished product has a continuous, robust structure thanks to the absence of seams.

Expanded mesh is the result of cutting and cold-pressing the raw materials (rolls or sheets). All the expanding machines we use have been designed and built in-house. We constantly optimise these to ensure the excellent design and quality of our semi-finished products, plus great flexibility when producing mesh to order.

The shape of the blades used to cut the sheet metal determines the shape and size of the expanded mesh. The semi-finished product has a continuous, robust structure thanks to the absence of seams.

Our expansion process produces no waste. This makes for efficient use of the raw materials and excellent output levels, hence our attractive prices.

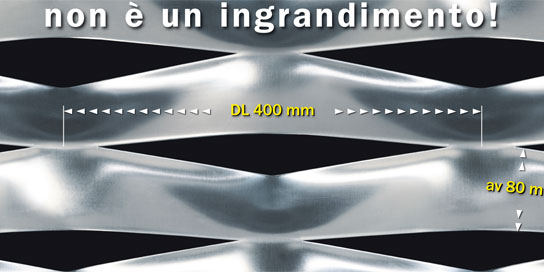

Fils' experience in manufacturing expanded mesh has led to a professional range of meshes that can easily be personalised in terms of shape, size and the thickness of the material. In the ULTRA LIMITES architectural line, the DL (long way pitch) is always longer (even 400 mm) to produce great visual effects. Mesh can also be made to order.

Many materials can be deep pressing: carbon steel, galvanised carbon steel, stainless steel, aluminium, copper, brass, titanium, other metal alloys and non-metallic materials.

Expanded mesh comes as rolls and sheets, of standard commercial thickness and dimensions. Use the PRODUCTS menu to get full details of each item. Expanded mesh can be cut to measure, rolled or flattened to its original thickness.