The term 'expanded metal' or 'expanded metal mesh' or ’expanded mesh’ means a material that derives from a coil of solid sheet metal that is ‘stretched’, that is, engraved and stretched simultaneously by cold forging. When the solid sheet is 'stretched' an open part is formed, called 'mesh' which can have different shapes, depending on the tools used during production.

In the following sections, all information about expanded metal is available.

If you want to better know these materials and you are interested in the technology process, you can read the article What is expanded metal?

Here you can find:

- How the expanded metal is made: the expanding process

- The main shapes/geometries of the expanded metal

- Wide assortment of materials

- How to measure expanded metal mesh

- What is expanded metal used for

- Advantages and benefits of expanded metal

- Some of our best achievements with expanded metal mesh - The Archiexplorer Project Portfolio

- Request for quotation free service

The main types of expanded metal

The expanded metal can be manufactured in different shapes and sizes: Fils offers also specialised metal meshes for architectural purposes.

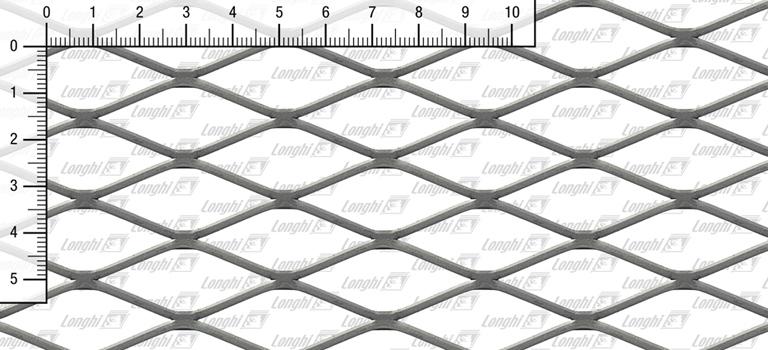

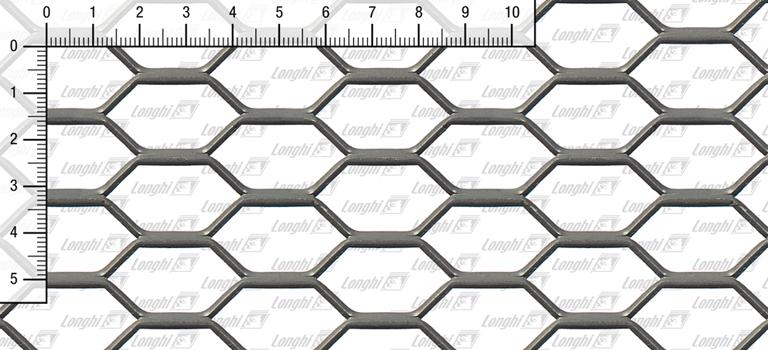

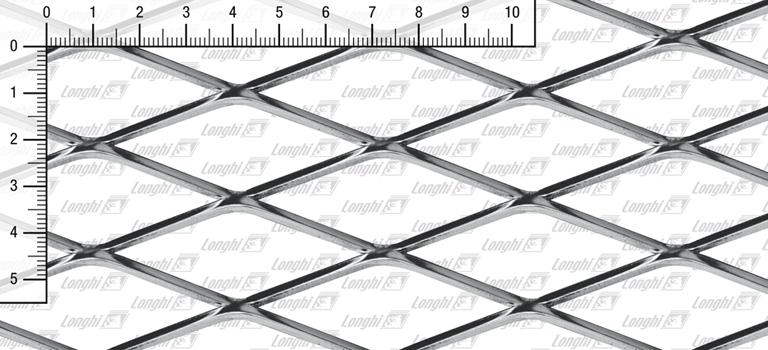

From the various shapes of the 'knives' that stamp the solid sheet metal, the geometries of the metal mesh are born. For example, the rhomboidal expanded metal is born from the triangular tooth mold, the hexagonal mesh is born from the trapezoidal knife. By combining the different processing parameters, all the different varieties of models proposed by Fils are obtained.

The various types are suitably described in the dedicated subsections and are characterised by size and design.

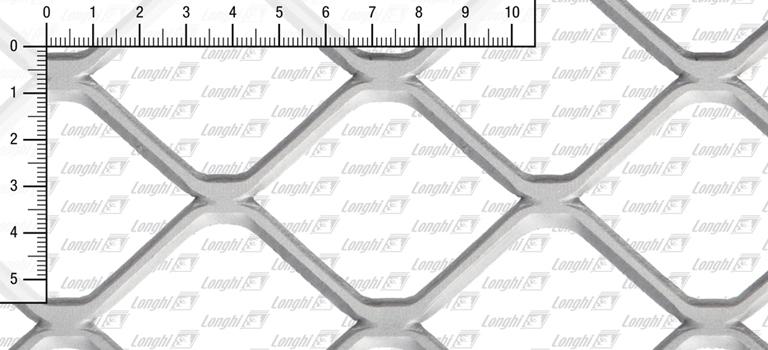

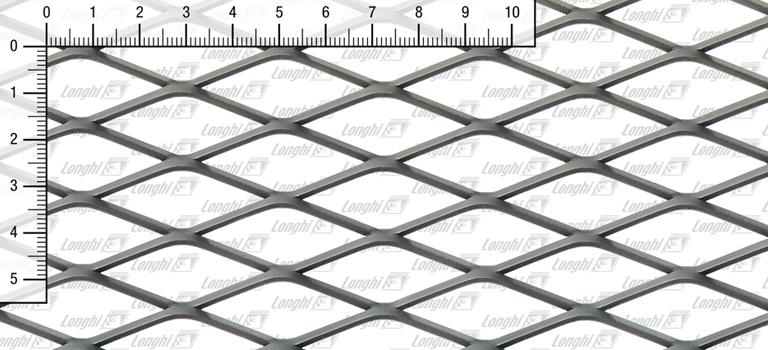

The Square Mesh range from 16x13 mm to 120x87 mm while the Hexagonal-toothed range from 35x15 mm to 62.5x25 mm. The rhomboidal expanded metal: has a pleasant aesthetic effect and an excellent functionality for the passage of light and air.

The smallest size has very resistant 10x6 mm meshes with a weight of 3.2 kg / m2 while the larger one is 200x75 mm and a weight of 5.1 kg / m2. Inside there is a wide range of sizes. See the Table down here.

| Type | RANGE FROM | RANGE TO |

|---|---|---|

| SQUARE MESH | 16x13 mm | 120x87 mm |

| DIAMOND MESH | 28x10 mm | 200x75 mm |

| HEXAGONAL MESH - TOOTHED | 35x15 mm | 62,5x25 mm |

| PROTECH MESH (Architectural line) | 45x15 mm | 300x100 mm |

| ULTRA LIMITES MESH (Architectural line) | 350x120 mm | 800x300 mm |

Protection, aesthetic quality. All the advantages of the expanded metal

Using the right techniques for fastening to the substructure, expanded metal panels provide guaranteed safety in every type of use in building and construction.

Parapets and fences give the sensation of solid protection thanks to the sturdiness of the material.

These safe and practical solutions are ideal for:

- protecting people

- isolating dangers

- preventing risks

Load-bearing capacities for walkable surfaces are certified to Technical Construction Standard. Adequate protection is also provided for the respective stairs.

Anti-slip grating in expanded metal guarantees excellent non-slip results documented by the certification tests specified by DIN 51130 Standard and also anti-panic function.

Why is the expanded metal used in many industrial and architectural applications?

The reason for this versatility lies in the numerous possibilities of transformation of this material. Here are some possible processes for expanded sheet metal:

- Cutting to size according to the customer's design in simple but also complex shapes thanks to water cutting.

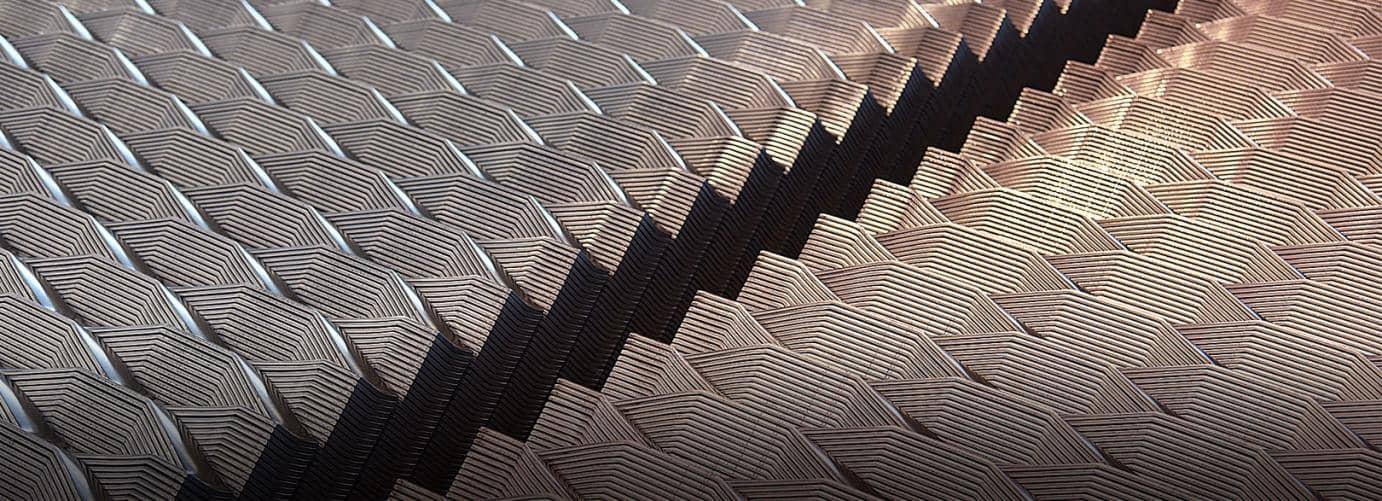

- Folding and 'pleating' according to the thickness of the starting expanded metal mesh. Special presses are used to achieve the desired result. How expanded mesh sheets are folded depends on the nature of the network. To do this, special high-precision presses are used.

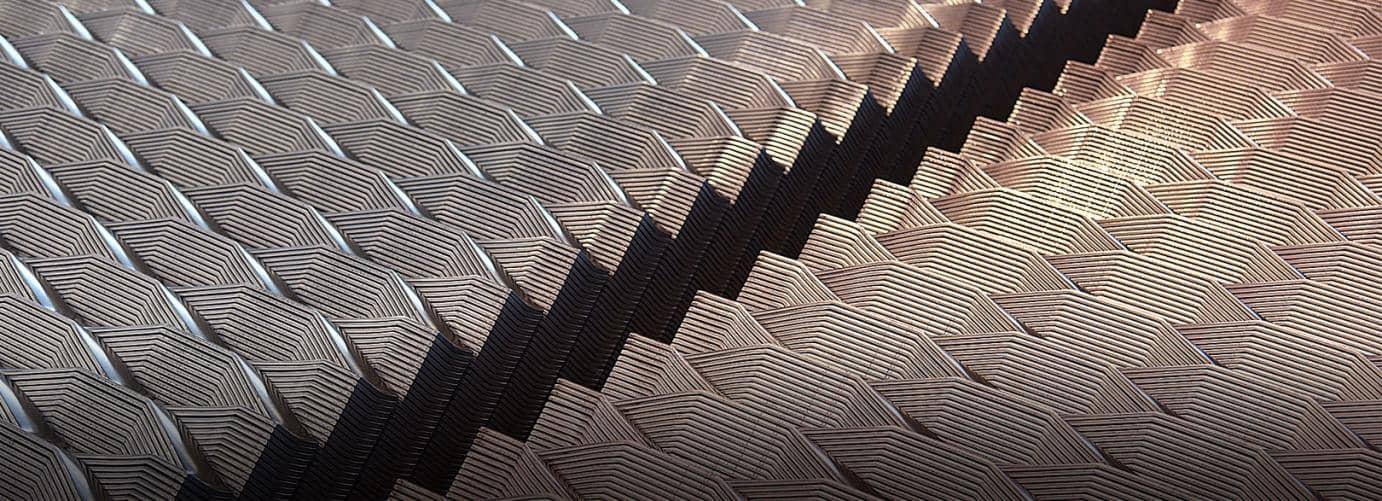

- Bending and waving to obtain the fluid effect that is in great demand today in the architectural sector. See, for example, the expanded mesh facades in the Toni Areal or Bocconi Campus projects.

- Edging with profiles that can also be used to fix the panels to the underlying structure. There are various profiles: C, L and U.

It is recommended to ask for support to optimise the time and costs of the project.

Sustainability: the environmental impact is rightfully being considered essential

Green energy

90% of the energy required for expanded metal production comes from photovoltaic systems.

Pollution-free process

“Expanding” is a cold-pressing process that does not require the use of pollutants.

Zero-scrap processing

Expanded metal is produced without any work scrap with the optimised use of raw materials.

Recyclable

At the end of its long working life, expanded metal is subjected to a differentiated waste collection for 100% recycling.

Some of our best achievements with expanded metal mesh

The architectural design of the International Congress Center in Katowize, Poland, won first place in an international urban architecture competition. Its construction is based on noble materials. The outdoor area and lobby are fully characterised by a bright black expanded metal mesh and the conference interior is made of wood and concrete. Together, they create the perfect space for various types of corporate events: congresses, conferences, training, trade shows, entertainment and more.

In Rotterdam, the Netherlands, the NAI (Netherlands Architecture Institute) is an archive, museum and library all rolled into one. It holds important archives and collections of Dutch architects after 1800 and makes them accessible to the public. The NAI is now part of the New Institute. Its facade is made with 'HYBRID' expanded metal, with configurable transparency to allow visibility and protection at the same time.

Interested in cladding, facades, false ceilings, parapets or architectural applications? Read the article about our creatives line for cladding surfaces.

Expanded metal prices

Expanded metal prices vary according to the quantities and models required.

Contact us for more information.

Our company: in the following video you can find out more about our company and expanded metal production. Enjoy it!

Let's continue and explore all the expanded metal models.