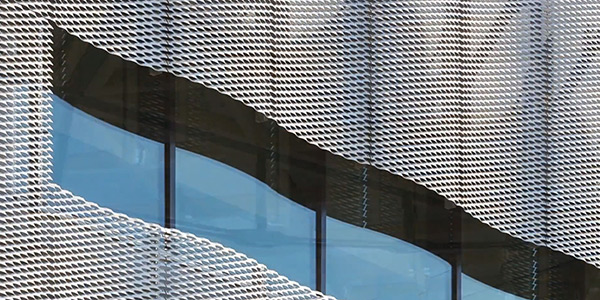

Immagine header

Ideas take shape with expanded metal at the National Automotive Innovation Center (NAIC), Warwick. Walking around the campus at the University of Warwick (UK), the eye is drawn to the beauty of its imposing facade.

This prestigious building, officially opened by Prince Charles of England in 2020, will long into the future house the latest advances in automotive technology and provide the expertise needed to keep the UK competitive globally.

The philosophy that guided the project was the complete integration between all departments and functions of the NAIC to maximize the exchange of ideas and information.